In recent years, although China's hardware and tool ind […]

In recent years, although China's hardware and tool industry has developed a lot, it has lagged far behind the development of the machine tool industry. According to data, China's current annual tool sales are 14.5 billion yuan, of which cemented carbide tools account for less than 25%. Not only is it far from the international market tool product structure, but also can not meet the domestic manufacturing industry's growing demand for cemented carbide tools Demand.

At present, the unbalanced tool structure is that the produced tool is out of line with the demand. For example, the gap of carbide cutters required by users is large, but the production of high-speed steel cutters is excessive; the gap of high-efficiency cutters urgently needed by modern manufacturing industry is large, but the production of low-grade standard cutters is excessive. Luo Baihui, Secretary General of the International Mould and Hardware Plastics Industry Suppliers Association, believes that from the perspective of the technological development trend of the machinery manufacturing industry, the proportion of high-efficiency CNC machine tools in our factories will increase year by year, and the demand for efficient advanced tools will increase rapidly , And the demand for traditional standard tools will decrease year by year.

China is a major producer and exporter of hardware tools. Among them, most of the power tools sold worldwide are produced and exported from China. China has become a major supplier of power tools in the world. Although China's hardware tool industry is relatively large, many hardware tool manufacturers often lack core competitiveness and are difficult to grow larger and stronger due to factors such as weak technological innovation capability, over-single market structure, and weak brand influence. Luo Baihui pointed out that due to insufficient independent innovation of domestic tool companies, they only focused on the benefits of short, flat, fast and low-end products. Renewal investment, faced with the lack of patience for basic research in the face of market changes, always have the wait-and-see mentality, waiting for other companies to develop new products, take a simple analysis of the results, adjust slightly for finished products, blindly follow the trend to the market Ignore market saturation and business needs. Often, this type of follow-up development with quick success and short-term success can only rely on other excellent foreign companies, losing the leading power of development and innovation, and the overall system level of the product is always hovering between 80% and 90%; due to the lack of exploration of deep product technology The ability to re-innovate is weak, and it can only stop at product development that looks like a god.

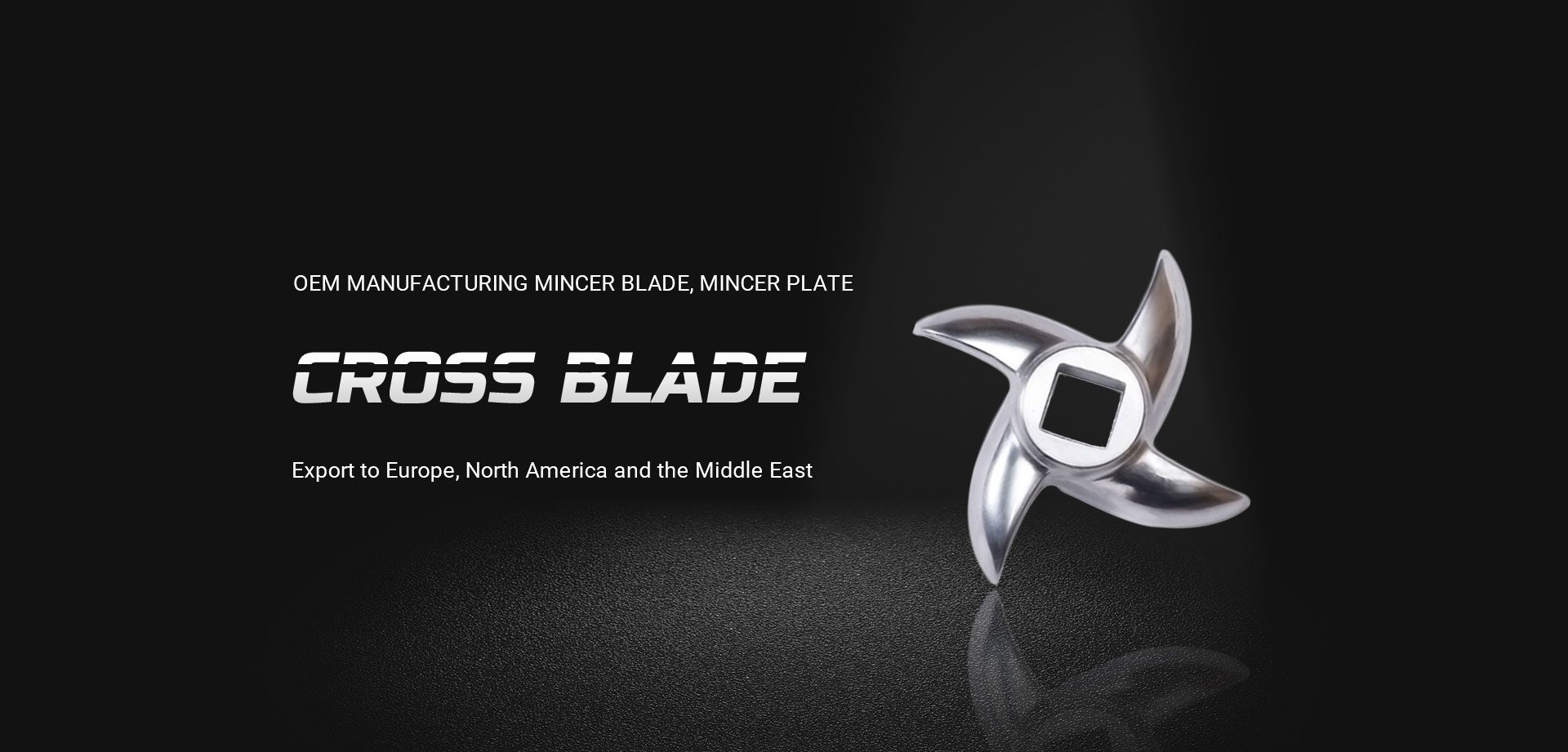

Copyright © Fenghua Zhuoyue Metal Products Co., Ltd. Rights Reserved. Support by: HWAQ

Location: No.238,Huimao Road,Jiangkou Street,Fenghua ,Ningbo City ,Zhejiang Provience ,China

Phone: +86 13805834365

Email: [email protected] China Meat Grinder Knifes Manufacturers